TELLING TRUE STORIES

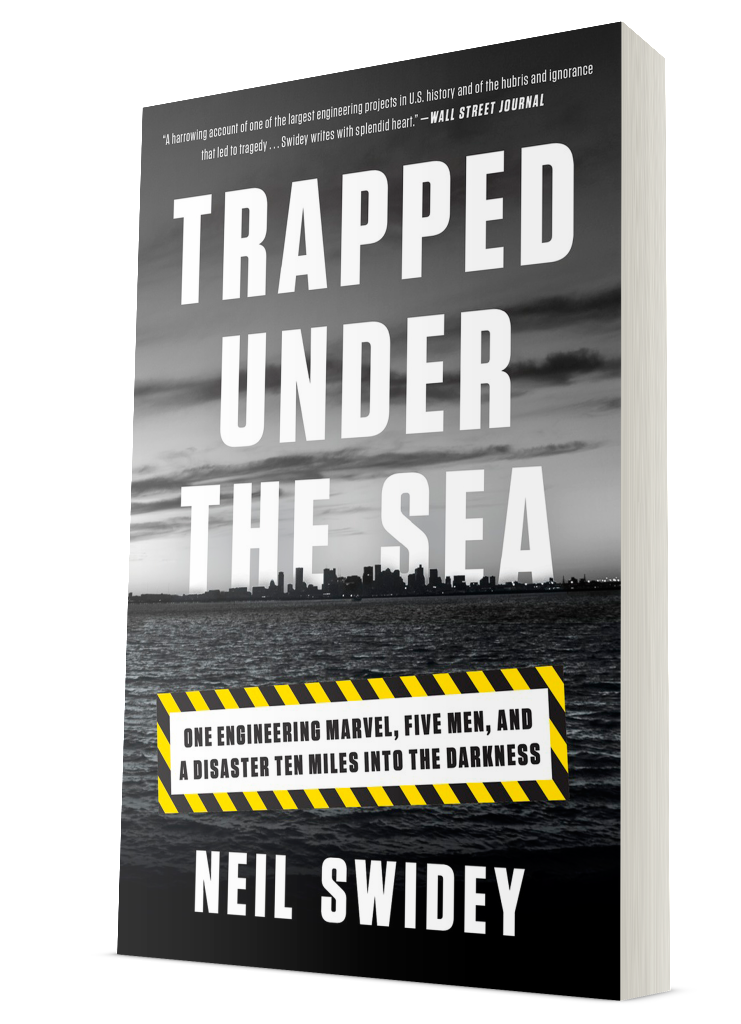

NEIL SWIDEY is a narrative nonfiction author and journalist. His most recent bestselling book, TRAPPED UNDER THE SEA, tells the gripping story of five men who were asked to do a nearly impossible job. They were sent to the end of the world's longest tunnel of its kind, which had been built deep under the ocean floor and was by then starved of all light and oxygen. Tragically, not all of them made it out alive. Swidey takes you into the exotic world behind a wondrous megaproject, and introduces you to the fascinating real-life characters asked to rescue it. The result is a taut, action-packed narrative that was named one of the best books of the year. Reviewers have described it as "impressively reported" (NEW YORK TIMES BOOK REVIEW), "a masterfully crafted saga" (BOSTON GLOBE), and "a cautionary tale, which Mr. Swidey writes with splendid heart" (WALL STREET JOURNAL).

About Neil

NEIL SWIDEY

is a bestselling author and award-winning magazine writer who explores a wide range of subjects in his work. He is a professor of the practice and director of the Journalism Program at Brandeis University and editor-at-large of the Boston Globe Magazine…

Recent Work

The Good Doctor

Harvard-trained physician Jim O’Connell agreed to spend a year caring for homeless people in Boston. That was 40 years ago. He’s been doing that same work in “blessed obscurity” ever since, but the obscurity ended in 2023.

December 12, 2023

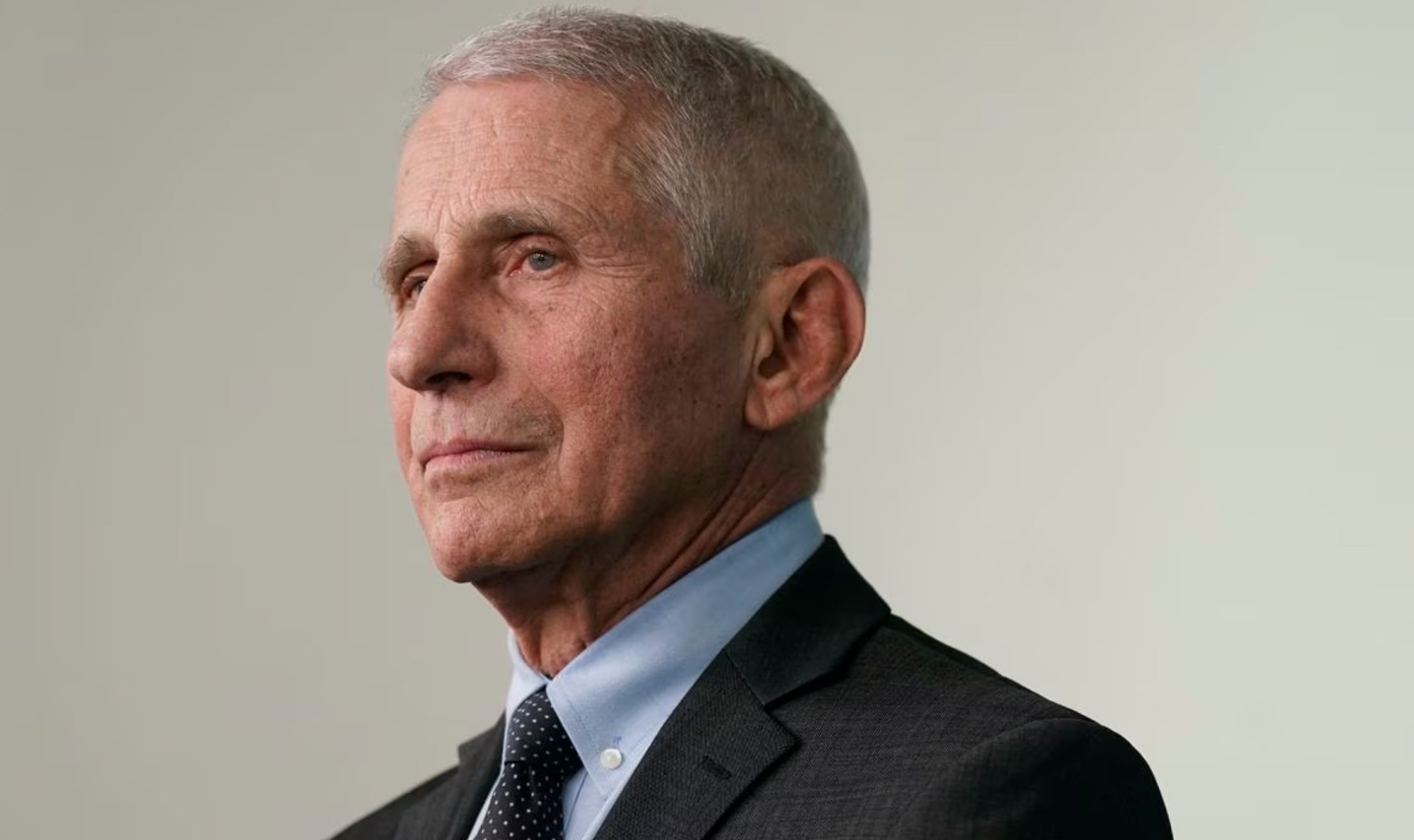

The Dr. Fauci Exit Interview

The face of the nation’s pandemic response talks about future preparedness, political division, and one thing he’d have done differently.

February 23, 2023

The Virus’s Tale: A COVID narrative investigation

Track the coronavirus pandemic in Massachusetts to its roots and you find a story driven by heroics, ingenuity, error, pain, and a hard question: How could a state famous for health care excellence have suffered such a vast loss of human life? (See Awards.)

May 31, 2020

‘You don’t understand, Captain. He has a gun’: The hijacking of Flight 1320

An Eastern Airlines shuttle from Newark to Boston 50 years ago started out routine. It ended up changing how America flies. (See Awards.)

March 20, 2020

In The News

Trapped Under the Sea featured as a clue on Jeopardy!

“The Virus’s Tale” narrative investigation/documentary on COVID-19 wins a national Edward R. Murrow Award from the Radio Television Digital News Association.

“The Hijacking of Flight 1320,” “The Virus’s Tale” and “Dispatches from the Edge” win national awards from the Society for Features Journalism.

Special report on college sports wins the Society of Professional Journalists’ Sigma Delta Chi Award for magazine investigative reporting.

Speaking Engagements

Neil Swidey engages with a variety of audiences, offering powerful, widely applicable lessons from his years of book research into the forces that can lead very smart people to make very costly mistakes.

Website by Melanie Litwin